SOURCE TO STREAM, CLEAN, CONTAMINANT FREE DRINKING WATER

2023 - NO RATE INCREASE!

Updated 10/4/2023

The H2GO water lines have been flushed. There are a few dead-end lines still to be flushed, however, this is part of regular distribution system maintenance. If you’ve been waiting for the system flushing to end, there’s no longer a need to continue with your contracted outside water service.

The State requires public water systems to include disinfectant in the treatment of potable water. Chlorine residual in the finished water leaving the RO plant is roughly at 0.80 ppm, and in the furthest reaches of the H2GO distribution system the chlorine residual is about 0.2 to 0.3 ppm. For reference, 0.20 ppm chlorine residual is the lowest residual required and 4.00 ppm is the highest residual allowed per the State.

Some customers have reported noticeable chlorine taste in the water, this is to be expected after drinking bottled water for an extended period of time. If the chlorine odor or taste is bothersome, refrigerator filters and Brita type filters do reduce odor and taste of chlorine in drinking water.

CONSUMERS BEWARE

There are numerous water softener/filtration providers scaring consumers into unnecessary purchases.

Here is some helpful information:

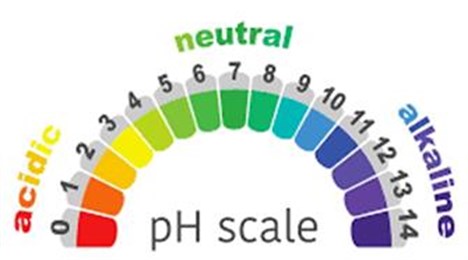

The water leaving the RO plant has a pH anywhere from 7.4 - 7.8.

Alkalinity is roughly 75.

Average hardness for the month of October 2023 - 72

mg/L CaCO3 (ppm).

TDS (total dissolved solids) Tests

TDS (total dissolved solids) tests are being used by softener/filtration providers and consumers to measure water quality. A TDS test is not a reliable water quality test.

The TDS test provides a whole number, with no indication of what the number represents. Electrolytes increase TDS, good minerals increase TDS.

Our water treatment process includes adding calcium carbonate, which adjusts the pH, hardness, and alkalinity, increasing the TDS count. The State required addition of disinfectant in a public water distribution system also affects the TDS whole number.

H2GO’S Water Supply - Clean and Free of Industrial Contaminants!

Distribution System Free of Industrial Contaminants

WATER TEST RESULTS

(June 21, 2023)

On May 30th, 2023, Brunswick Regional Water and Sewer turned on the Reverse Osmosis Water Treatment Plant pumping water sourced exclusively from contaminant free aquifers 400’ – 600’ deep, already confirmed with non-detect levels of manmade contaminants.

On June 5th, 2023 water samples were pulled from numerous locations within the H2GO distribution system to be tested for 40 different PFAS analytes.

The Board of Commissioners’ meeting held June 21st included approval of the 2023-2024 budget, which presented NO RATE INCREASE!

Update - 5/25/23

LELAND, NC – H2GO’s Aquifer-Sourced Reverse Osmosis Water Treatment Plant will begin pumping aquifer-sourced RO treated water into the distribution system on Tuesday, May 30th.

H2GO public water supplies are free of harmful contaminants such as 1,4 Dioxane, GenX and other per-fluorinated compounds. H2GO’s Reverse Osmosis treated public water supplies is the highest quality potable water in town!

On June 5th H2GO will pull multiple water samples from the distribution system and send them to an outside laboratory requesting expedited test results. H2GO will test for 40 different PFAS analytes, and will notify the public as soon as test results verify “non-detected” levels of the PFAS analytes in the distribution system.

“Our team has eagerly anticipated this day, and we know our customers have as well. Providing a new water source to our district is a crucial step in the right direction for our growing community. H2GO’s staff and commissioners are truly grateful for the tremendous support we’ve received throughout this major undertaking. Our team is committed to providing the highest levels of water and sanitary sewer services.

CLICK HERE TO LEARN MORE ABOUT THE WATER TREATMENT PROCESSES !

AQUIFER-SOURCED REVERSE OSMOSIS WATER TREATMENT PLANT QUESTIONS & ANSWERS